We have been working with a fit-out contractor who take an existing building and turn it into whatever the client wants, usually office or laboratory spaces. In a recent project, they have been fitting out an existing portal frame with a two-storey mezzanine to provide offices, laboratories, and a plant area.

In this instance, the recently built building had been designed to allow for a mezzanine, but the requirements weren’t well defined. There was just a requirement that the floor slab should carry an additional load. Having been in this position ourselves, we understand this gives flexibility to the tenant or new owners without the engineer having to design the mezzanine at such an early stage.

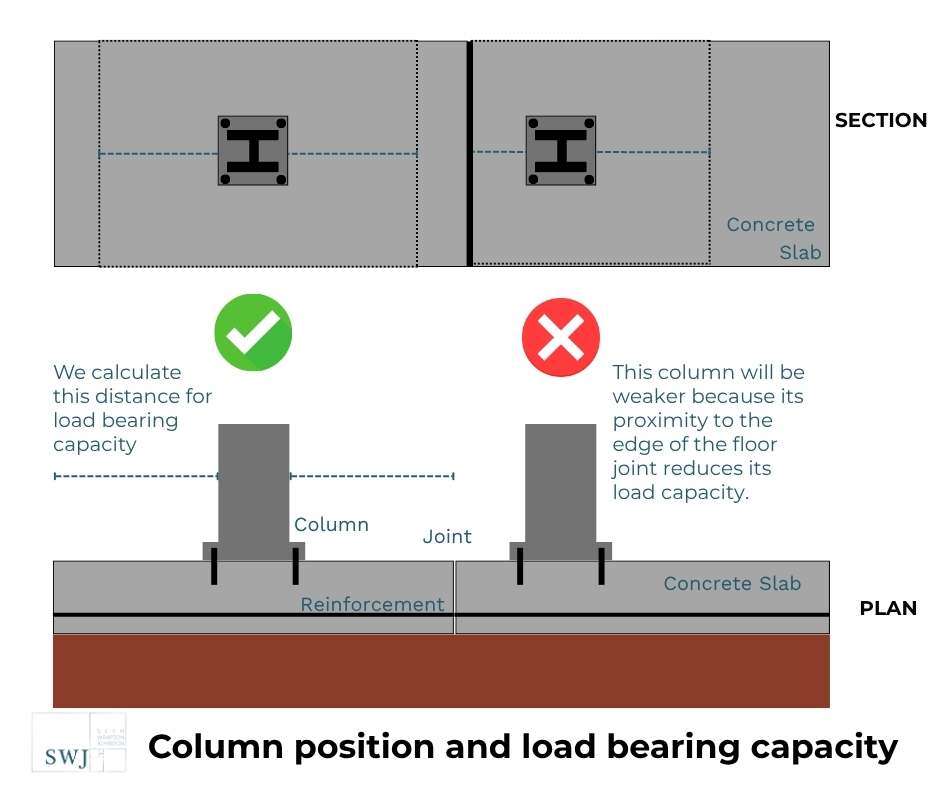

Unfortunately, this flexibility does still have some constraints, mainly the position and construction of the joists, and these had not been considered in the initial design of the mezzanine by the specialist subcontractor. While some columns sitting on the floor slab could carry quite a significant amount of load, others were immediately adjacent to a joint that couldn’t.

SWJ Consulting identified this issue during a site visit. Fortunately, the building was new and as such there were accurate as-built drawing records showing where the slab joists were and how that had been constructed. Once this information had been gathered, it was a simple exercise to overlay those as-built joint positions onto the base plate plan for the mezzanine to establish where there was a problem

We are now working collaboratively with the mezzanine designer to advise on where columns should or could be moved to, to allow them to provide an optimal mezzanine design and engineer a solution that avoids expensive groundworks. Adding new pad foundations would mean breaking out the slab and putting in the concrete pad. In this instance, it is a much more cost-effective strategy to redesign the mezzanine, to add more columns to reduce the point loads, or use longer beams to move columns away from slab edges and joints.

What if the existing floor slab isn’t suitable to support a mezzanine structure?

In this case, new foundations are most likely the required option. As mentioned previously, groundworks to break open the existing slab, excavate a pad foundation and fill with concrete before being reinstating the slab is labour intense and therefore expensive. In this case we would advise that the larger spanning floor beam, with less columns and larger point loads will reduce the number of new pads that are required to be formed and even though each pad might be larger, it will be cheaper overall. This why mezzanine designers or building owners and tenants looking to install a mezzanine should consult us early in the process to ensure these kinds of issues can be addressed in the initial stages and avoid delays and a redesign.

What to do if you don’t have as-built drawings?

If you don’t know these things or have access to record drawings, then investigations need to take place starting with concrete cores through the slab to establish its thickness. If you are lucky, you might strike some reinforcement, and with a couple of cores you can find out the spacing, and the reinforcement spec.

Finding out how the slab joints are constructed is a slightly harder task and usually means more manual breaking-out. By carefully breaking away the concrete around the joint the intention is to establish the type of joint that had been used.

Specialist Building Surveyor can complete the coring, testing to establish the concrete strength, and provide the reinforcement details as well as a building survey drawing showing where the slab joints are. Once we have this information we can work out if your floor slabs are suitable for the additional load of a mezzanine.

If the floor slab is not suitable and is unable to support any of the mezzanine columns, you could add Pad Foundations, as mentioned above.

A better solution would be to redesign your mezzanine, so that you have less columns, carrying more load. This is why it’s good to get an investigation done to establish what you are working with early in the project, this information can then drive your mezzanine design and layout.

When SWJ Consulting are designing a mezzanine from scratch, we not only look at the structural elements of the mezzanine but also ask questions of the rest of the design team, and the client, to obtain information that might not be freely available. If we’re working with a designer they may have information on the steel work, but no information on the foundations or the floor slabs.

Working Collaboratively with Structural Engineers

Another advantage of working collaboratively with structural engineers from the early stages is that we can help value engineer designs. It is not uncommon for mezzanine designers, to take the once size fits all approach. This means taking the longest span with the biggest floor load on it and designing that beam, and then using that beam everywhere. Whilst this approach is safe and conservative, and the beam will be more than adequate for any lesser span or load, it is not providing the optimal, most cost-efficient, use of materials or budget.

Unless you have got repetitive connections to make, where you wouldn’t vary joist sizes around the building (unless there are large savings to be made), we like to use the right beam in the right location, and the right column in the right location.

Future Proofing your Buildings

It’s important for clients, at the earliest stage of building design, to ask the same kind of questions, we as structural engineers would be asking to help future proof the building including:

- What will the space be used for?

- Is it just an office?

- Are we future-proofing the building for anything more than an office?

- Does the floor need to be concrete?

- Could there be a lighter-weight floor solution?

- Are the potential uses of the floors likely to be sensitive to vibrations?

- Are there plant or services that need to be supported or duct routes that need accommodating?

These are the questions we ask of our clients, and they are worth asking when thinking about commercial building design or even mezzanine design. By asking these questions, you will be able to improve efficiency and reduce costs in the long run.

Initial steps for installing a mezzanine

Whoever you use to design the mezzanine, it is important you ensure they are asking the same questions we would in the very early stages: joint positions, slab thickness, reinforcement details, and how joints were formed. If you don’t have this information, consult a Building Surveyor and Structural Engineer to establish the parameters of any investigations needed. The structural engineer will then take the results of the investigation and undertake some analysis. Your designer, whether it’s a structural engineer, specialist mezzanine designer or a turn-key supplier, will have all the information they need. Taking this approach will help to ensure you get a successful and achievable design the first time, potentially, without the need for pad foundations or a redesign.

Asking the questions we ask from the earliest stages and getting the right information about all elements of the building is what leads to optimal and efficient mezzanine design.

If you are considering adding a mezzanine to a building, or are at the early stages of commercial building design, and would like us to take a look at existing plans and solutions to see if we can add value to your project please do get in touch on 01993 225085 (Witney, Oxfordshire), Southampton 02381 920656 or mail@swjconsulting.co.uk.