At SWJ Consulting we pride ourselves on delivering practical and efficient solutions, backed by thorough investigation and engineering expertise. Collaboration and understanding are also important. Everyone involved in the construction of the project from the client to the contractor should have a clear idea of what is needed, so we take the time to ensure all details are completed and presented in such a way that they’re easily understood. While much attention is given to the role of structural engineers in project design, another key figure working behind the scenes to make those designs a practical reality is the structural technician.

Our technicians develop initial structural designs into fully detailed, coordinated models ready for fabrication and construction. At SWJ Consulting, we use 3D technology so we can model the project and inspect it from all angles, we can then share this with clients, architects and fabricators so nothing is lost in translation.

The Technician’s Role in Design Development

Once a structural engineer has defined the main structural elements—such as beam sizes, column layouts, and load paths, there’s still a lot of detail that needs to be added before the design is construction-ready.

This is where the structural technicians are invaluable. It is their job to interpret the engineer’s intent and turn it into a comprehensive, buildable solution that considers:

- Real-world constructability

- Architectural coordination

- M&E coordination

They are needed to solve any spatial and technical problems, refine connections, and ensure every element of the design will work in the physical world.

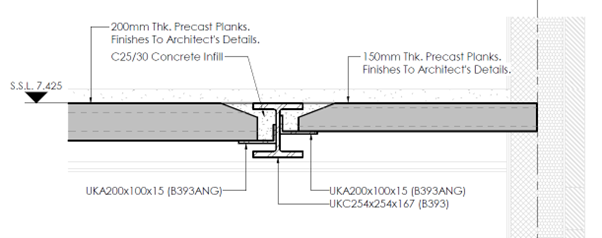

An example: Plates & Angles

Take a common structural element, like a steel beam, as an example of how technicians add value.

An engineer will complete the calculations on what beams are required but the technician will need to identify whether the beam is supporting anything, like a concrete plank directly and if so where it will be positioned, on top of, underneath or inside the beam.

This attention to detail ensures that when the steel fabricator receives the drawings, they have everything needed to begin manufacturing all elements without back-and-forth clarification.

This is where 3D modelling comes in handy as the technician can look at the beam that’s been modelled and bring in the architect’s designs (in the background) so they can see the walls, floors and beams and ensure the architect’s designs are followed, making any necessary changes to the placement of plates or steels in collaboration with the structural engineer.

We use Revit to generate our 3D models, coordinate, and present our designs. These tools help bridge the gap between engineer, architect, contractor, and fabricator. It helps with

- Visual clarity: Our clients and contractors can visualise complex connections and assemblies.

- Coordination: Integration with architectural and MEP models reduces clashes and rework.

- Accuracy: Automated schedules and drawing generation reduce errors and improve speed.

Getting the details right

Clients often focus on the big picture, cost, timelines, and overall efficiency. But the quality of the detailing phase can make or break a project, and it is important to get it right the first time. This is why we have invested in 3D technology and our technicians who use it. This makes the fabrication process smoother and faster as our drawings are clear and precise, minimising delays on site. The final structures reflect the original design intent, safely and efficiently, because 3D modelling allows us to see the architect’s drawings and design the structural connections accordingly. Avoiding any miscommunications or redesigns.

From steelwork detailing to final construction drawings, our technicians are a critical part of the delivery process, and their contributions are not to be underestimated.

If you would like to discuss a project, or for more information give SWJ Consulting a call on 01993 225085 (Oxfordshire) or 02381 920656 (Southampton) or email mail@swjconsulting.co.uk.