The title of this article is a little misleading as there are very few ‘cons’ or arguments against a move from 2d to 3d detailing, the only issue we have seen is the slowness at which the technology has been developed .

Why is 3D so much better?

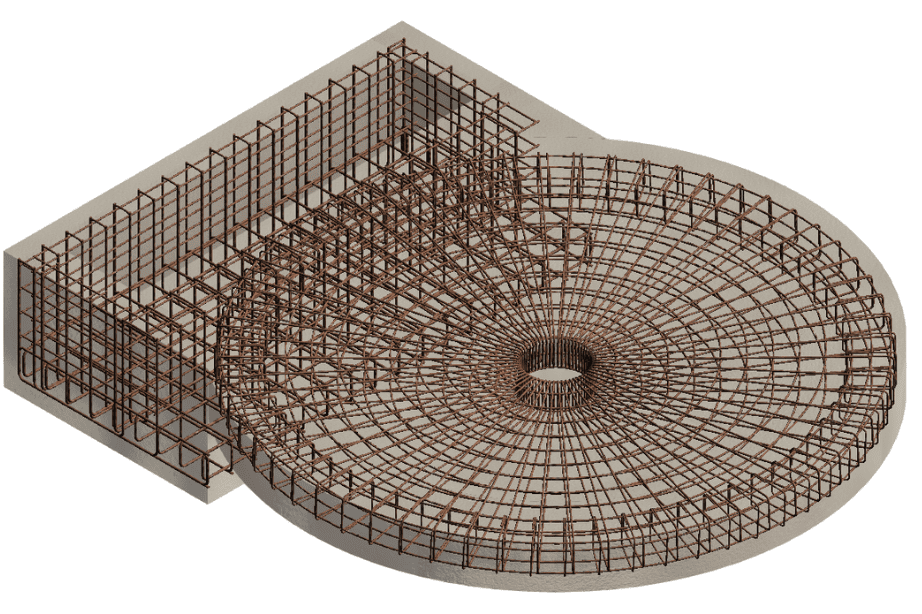

Essentially designing concrete reinforcement is to design an actual 3D element. To imagine it in 3D, draw it in 2D, reinterpret its effectiveness in 3D and then redraw with any changes in 2D and repeat the whole process again leaving room for human error and misinterpretation. 3D modelling enables solutions to start and finish as 3D models – able to be used in collaboration with other 3D elements of the building design.

These days most projects employ some form of 3D modelling for the main architectural, structural and M&E elements. The introduction and development of BIM since the early 2000s has encouraged this for all elements of the project including the reinforcement bars. Although the industry has been quick to move on BIM requirements the move to 3D reinforcement has been slower. Why? Because 2D reinforcement still works, it’s just not as efficient and it certainly does not allow you to visualise an accurate model that contains all the necessary data needed for collaboration.

Limits of sticking with 2D

We are moving on from 2D for several reasons but increasingly we see that remaining 2D limits our services. We don’t want to lose our competitive edge, our margins or hamper our workflow when there is an option that allows us to be more accurate and efficient and keep pace with the industry as it perpetually moves towards further automation and digital solutions.

The move from 2D to 3D reinforced concrete detailing Part 2

Traditionally reinforced concrete detailing has been a hand-drawn process. It then moved from being hand-drawn to being available digitally in CAD, but still in 2D. Now with increasingly sophisticated software and the increasing requirement for BIM and collaboration reinforced concrete detailing is benefiting all parties; the structural steel detailing industry, contractors and structural engineers.

SWJ Consulting has made the move from 2D to 3D for several reasons.

Long term improvement in quality

The need to take a 3D object and translate it to a 2D drawing of the solution that then needs to be reinterpreted back into a physical model is time consuming and vulnerable to error. 2D drawings can only ever be accurate to a point. A 3D solution improves not only quality but efficiency.

Long term increase in speed of detailing

Once we have got over the initial implementations and learnings of using 3D detailing it will enable us as a consultancy to improve the speed of producing detailed drawings and any subsequent changes as we can do them in-house and make changes that we can see ‘live’ in a 3D model without the need to reinterpret from 2D to 3D.

Offer our clients a more visual representation

Not all of our clients understand what is required of reinforcement or can understand 2D reinforcement drawings. A change to 3D enables us to improve communication with those less experienced at looking at these kinds of details, so they can understand what is required and be confident in all decisions.

Improve our workflows to be more efficient

By embracing this technology we have been able to create models and use them for our Finite Element Analysis within SOFiSTiK. It’s the next step to streamline our workflows.

What tools are we adopting to move from 2D to 3D?

Russell Wrapson is the lead in Digital Construction Methods and all things BIM at SWJ Consulting. It was Russell that investigated the practical requirements of moving from traditional 2D methods (line, dots and excel schedules) which he had spent a professional lifetime perfecting, to more advanced 3D detailed models embedded within our Revit models.

Unfortunately, the core tools within Revit for reinforcement detailing were too limited for what we needed and so Russell searched for suitable plugins to assist with annotating, scheduling and providing other general detailing tools.

At one point SWJ did consider moving away from Revit and seeking a completely new solution but having spent 10 years developing our personal Revit capabilities we decided to work with the software and find the relevant plugins.

The third-party tools that were available we tried and tested with limited success. Some plugins were not particularly user-friendly or didn’t allow you to override the commands. We are not going to allow a piece of software to dictate how we detail concrete especially if it is not in accordance with the standards.

We were disappointed with the options out there. Some plugins looked like they were being made to fit the solution but were missing the mark. Some were closer than others but nothing met our needs or standards.

How is the move going?

At the start of 2020, we decided as a company that it was the right time to fully embrace the change from 2D to 3D having dabbled with the idea over recent years. So we made a commitment to start developing our understanding of the core reinforcement tools within Revit. We finally found a suitable plugin in the form of CADs 3DRC plugin for Revit.

Since then, throughout the year we have been working closely with the Technical Support team at CADs, who are supporting us with our ongoing learning and we feed back to them on any issues we have found to help them improve the technology going forward. CADs have been able to add extra functionality to the plugin throughout the year and we are happy with the way the tool is working for us .

Our next instalment of our 2D to 3D reinforcement journey on how it went, in reality, is coming soon.