As part of our series of value engineering blogs, we are looking at how SWJ Consulting can save budgets by choosing the right materials for the job.

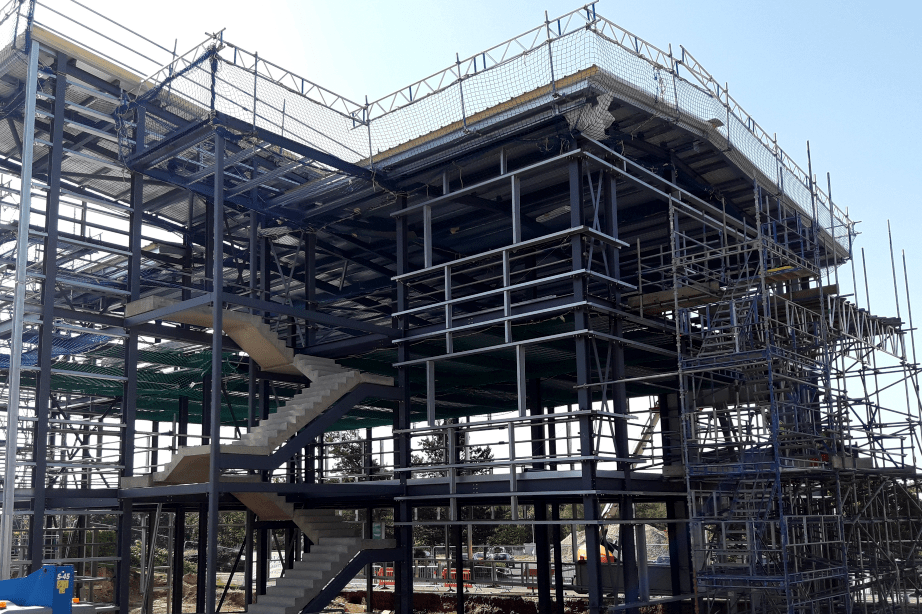

Saving money by choosing the most efficient steel frames for the job

There are several options when it comes to steel frames and situations where one choice makes more sense than the other. Our role at SWJ is to value engineer the use of steel frames and recommend the most efficient scheme for the project. We are able to propose alternative solutions such as lightweight inner leaf or Westoks which may not have been considered or are met with scepticism. However, the real edge is we have the technology to quickly test these solutions to prove their validity and can even provide tonnage comparisons to your surveyors so you can be sure you are getting the best value scheme.

Using our knowledge, expertise and technology to challenge assumptions and look at every element of the design for a more efficient solution that will help contractors win the contract and provide value for the client is why SWJ Consulting has a reputation for proven designs that add value.

In this blog, we are going to look at the possible advantages and (read a simplified pros and cons blog) of the various options when it comes to steel frame options and our opinions overall on the two choices.

Composite Slabs v’s Precast

Precast slabs

Precast slabs are quick to install and give you a safe working platform immediately. This immediacy could therefore make them more cost-effective for the programme if not on the budget. They also provide an effective diaphragm to restrain the beams and help to distribute lateral forces.

That said, precast slabs are more difficult to install around bracing therefore additional temporary works may be required. Beams will require propping during installation to stop them from twisting until the precast slabs are grouted. Overall, they account for the heaviest steel sections due to the extra fabrication bottom plate and angles to support planks.

Composite Trapezoidal Decking

Composite beams provide an economical steel design by increasing the effective depth by including the floor structure in the compression zone. The trapezoidal decking can be lifted at the same time as the steel frame which means a reduction of crane hire time-saving budget and time. If there is a raised access floor, then they can be installed straight on top and do not require screed. Composite is a great alternative to Deep Deck.

Unlike precast composite requires curing time for the concrete before it can be walked upon. Reinforcement must be fixed on-site before the concrete is poured and then left to cure. Depending on the spans required additional secondary beams may be required or temporary propping during the concrete pour.

Overall, in many cases, a composite solution offers a far more economical design, the reduction in the overall tonnage of steel offers potential savings within the ground therefore it is one of the first options we will consider when reviewing a design. Depending on usage and the loading we think that about 75% of the designs we look at could be made more efficient with a composite floor. However, in line with our design principles, we take a full holistic view of all the conceivable constraints on a project before deciding on the most appropriate solution.

In several recent cases, our fee for the structural design has been completely offset by the savings we have made, effectively meaning we worked for free.

Westoks Cell Beams v’s Solid Beams

Westoks are an expensive option but their flexibility often creates savings that would not be possible using standard open beam sections and prove to be far more efficient on the bottom line. We used them to great effect on the Aston Martin showroom we designed in 2017 for many reasons.

Westoks can achieve longer spans with lighter sections than standard open beam sections, the elongated holes allow for the M and E services to be incorporated, without the need for additional beams.

Using Westoks can result in a lighter overall structure which means reduced foundation sizes.

As mentioned, price is often a barrier for Westoks. They are considered an expensive option and have a longer lead time as they are bespoke. Sometimes, Westoks are deeper than the standard section which can affect head heights, which is a consideration that needs to be discussed as early in the project as possible.

Open Beam Sections

Open beam sections such as UKB’s and UKC’s are the industry norm and the better-known option. They are readily available and have a more ‘competitive’ price than Westoks.

However, they are considerably heavier and offer reduced flexibility for services. To accommodate bigger holes for services we may have to design oversized beams.

The weight of solid beams means there is a chance you will need bigger foundations, but this depends on ground conditions.

Our recommendation for Westoks or solid beams depends entirely on the size of the building span and how heavily it is serviced (office and commercial as opposed to residential). It is these factors that govern the design route. We look at the options and work out the most efficient design using our virtual design technology that allows us to quickly test the options and recommend the most efficient of the two options.

Lightweight steel frame inner leaf vs traditional construction

In the UK the default is traditional construction, bricks, and mortar particularly for commercial developments that are perceived to need a more robust option.

Lightweight steel frame inner leaf removes a large amount of dead weight, requiring smaller beams and savings in foundations. They are fast to install making buildings watertight quickly thus leading to program benefits.

A lightweight inner leaf is not generally considered a robust option, but this is not always the case and depends on the situation. Some clients may just demand bricks and blocks because it is what they know when there is a lighter alternative to heavy masonry.

Depending on the situation it is used in, lightweight inner leaf walling provides a suitable alternative, that is cost effective and has adequate performance, however in certain cases the use of this system does not provide the necessary robustness and the use of traditional block walling would remain the preference, for example, a sports hall or bin store.

Although masonry is more robust it does take more time to lay and is weather dependent. Conditions such as freezing temperatures and heavy rain can postpone a masonry lift.

Added value as well as value engineering with SWJ Consulting

SWJ Consulting has a breadth of experience and the technology that enables us to challenge assumptions and question obvious choices that may not be the most efficient. We have the technology to quickly test and prove our ideas and the confidence to quote at risk where needed.

Value engineering is about finding a solution in the most efficient way, saving materials, labour, time, and budget. This approach not only benefits the environment but our contractor client’s and their clients too.

If you would like to work with us on your project and find the most efficient solution for steel frames and all elements of your design, then please give us a call on 01993 225 085 or email mail@swjconsulting.co.uk